Denker's Metalworking Project

Page

Contents:

Lathe

Multi-Stop (New)

Micro

Drill-tap Adapters (Changed)

Mill

Tapping Head (New)

Quick

Change Tool Post Set (Changed)

Reciprocating

File (New)

9" Disk Sander

This

was one of my very first projects. It is made mostly of wood but does have some

0.18" thick steel parts that I laser cut at work. I used a 1-horse

1725-RPM motor. It was originally made for wood but works very well on metal. I

added the SCOTCH-BRITE deburring wheel later (runs

about 3450 RPM) and it can be removed if necessary. The table can tilt down 45°

and has a groove for a slide guide. This sander gets used often.

Boring Head

The

workspace between the mini mill head and the worktable is quite limited.

Because of this I use a set of screw machine drills which are shorter than normal

jobber drills. I didn't want to by the common 2" boring head for the same

reason - so I made my own. This head was made from 1" x 2" steel bar

and uses 0.375" diameter tools. It mounts in a 0.75" diameter holder

and extends down from it about 2". It works for diameters up to about

2". This design has a socket head cap screw that must be loosened to make

adjustments then tightened again.

Cutoff fixture

Unless

you want to buy all your hardware to needed size, you will need to cutoff

bolts, pins, and shafts from time to time. I was doing it often, so I came up

with this fixture. It uses a 26-RPM geared motor turning a 1/2" chuck and

a DREMEL with a 1.5" cutoff wheel. (The one in the picture is wore down) I

can move the cutoff wheel away from the chuck about 3" so fairly long

parts can be cut off. I have cut everything from brass screws to hardened round

tool bits.

Lathe Grinder fixture

When

I need to cutoff something bigger, I use this fixture on the mini lathe. It

uses a CRAFTSMAN tool grinder and it is quite big. (The tailstock must be

removed) This thing runs at 25,000 RPM and can vibrate a bit so everything must

be tight. TIP: place wet shop rags under the grinding area and on wear surfaces

to catch the grinding dust - grinding dust and oiled machine wear surfaces

don't mix. Clean and oil the machine when done!

In the next picture I am cutting off a

hardened 1/2" bar using a 3" cutoff wheel. Also shown is a SCR motor

speed controller.

Mill High Speed

Spindle

The

CRAFTSMAN tool grinder used in the above project can also be used on the mini

mill to make a high speed spindle. The spindle is mounted in a 3/4" R8 collet and the drawbar is replaced with a threaded

0.26" I.D. x 0.50" O.D. steel tube. The grinder and its mounting

bracket are then mounted on top of the mill. I am using a SCR motor speed

controller to control the spindle speed. Notice I placed a lock on the mill

power switch to make sure I don't mistakenly try to turn it on.

The

next picture shows all the parts made for this project. I used ball bearings

rated at 43,000 rpm for the spindle but they are quite small and I am not sure

how well they are going to hold up. The collet and collet nut are purchased ROTO ZIP CT250 (0.250" dia.)

or CT125 (0.125" dia.) replacement parts. The drive shaft that goes

through the drawbar is 0.187" diameter. Plastic was used on the grinder

mounting bracket to help reduce vibration.

The next picture shows the spindle in

a 3/4" R8 collet with the hollow replacement

drawbar attached.

Index Fixture

If

you want to make any kind of marked dials, it is nice to have an indexing

fixture. This one was made using a purchased replacement lathe spindle, bearings

and other parts in a surplus steel casting. (not available anymore) The index

and vernier plates were laser cut at work and gives

me 3 ranges to work with. (28, 360 and 200) I can also mount other index plates

to it. The spindle can use a lathe chuck or MT3 collet

so there is nice versatility. (also has a 0.81" diameter through hole) The

marked dial on this fixture and many others were made using it. There are cheap

5C collet index fixtures available if all you want is

the 360 step range or of course you can use a rotary table.

I also made the tailstock shown in the

picture.

Lathe Ball &

Radius fixture

This

is a ball and radius fixture I made for the lathe. It uses a 0.375" tool

bit that can be set with a micro dial (0.050" per rev.) and can handle

parts up to about 2" in diameter. This is a good design for making ball

ends but somewhat limited for large part radius edges and special radius

shapes.

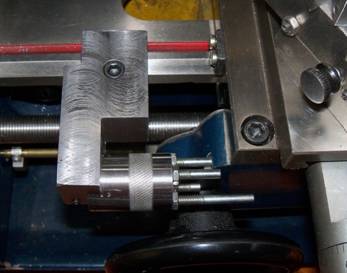

Lathe Carriage

Micro-Stop

Before

I made this stop, I used a hand wheel and dial on the lead screw shaft or the

compound rest to get the depth of bores etc. This works so much better. To use

(with the machine off) I set the cut tool against the gauge surface of my part

and with the micro-stop set to 1.000" bring it up against the carriage and

lock it down. Then dial back the micro-stop the depth of the bore or cut and

it's set. For more than 1", I use a spacer when setting it up. Both the

lock lever and the stop use 1/4-20 L.H. threads. This design has a low profile

and fits under the chip pan that I added to the carriage. I use this stop

often!

Lathe Knurl fixture

I

have two knurl tools. A scissors type diamond pattern tool and this straight

knurl fixture. I made this because I didn't want to buy another scissors tool,

but for the mini lathe the scissors tooling works best. To keep compound slide

screw forces to a minimum, I went with a bottom up design. This puts all the knurl

pressure on the lathe bed.

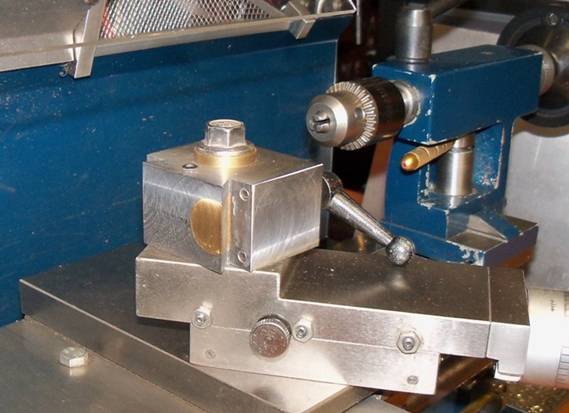

Lathe Multi-stop

When

making parts in quantity, it is nice to have more than one stop in the setup.

This is like others out there for other lathes but this is made for the

Mini-Lathe. It has 4 positions and each stop can be set to a desired length and

rotated into position as needed. Each stop has over 1.0" of usable 1/4-20

threads for setup and I have longer stops if needed. (The 3 stops not in use

will normally fit under the Cross Slide.) There is also an additional

unthreaded 0.250" dia. hole in the main part of the assembly for a fifth

longer stop that can be inserted and removed as needed.

Micro Drill-tap

Adapters

For

small drill sizes you really need a micro drill adapter. The mini-mill has too

much head weight to use with small drills. I made this one with a 1/4"

chuck and with the addition of a reverse switch on the mill, I can use it with

small taps too. (Spiral point taps in through holes) The outer shaft is 0.625"

diameter and the inner shaft has 0.80" of spring loaded movement. A

knurled aluminum collar pressed on a ball bearing is mounted just above the

chuck for easy hand control. Above the bearing is a rubber o-ring to deaden any

release shock. (Tapping only works if a reverse switch is added to the mill)

For

taps above #6 to 1/4", I took a tap wrench and modified it for the mill.

It is now a spring loaded floating tap holder with a 0.625" dia. mount and

about 0.65" of usable movement. With the lower speed addition to my mill,

it will tap 1/4-20 in steel with no problem.

Mill Tapping Head

I

had this old Craftsman drill head from an electric drill that the motor went

bad on and I decided to convert it into a mill tapping head. This is on old

metal housing drill so I think it is pretty heavy duty. The gearing is a little

over 12:1 so plenty of power is available. I had to rework the drill some for a

good mounting surface and bigger mounting screws. The old motor shaft was cut

long enough to press fit a new 0.500" dia. straight shank on it. I used a

0.500" bronze bearing to hold it in place. The output is about 0.70

forward of the input and the head is just over 2.50" long so I had to make

a short tap holder to keep it usable. So far it has worked great. I have tapped

steel using a 7/16-14 CNC style tap (not a hand tap) but would not want to do

it with anything bigger. The holder will take up to a 1/2" tap. This is a

float tap system and should be used with through holes or holes deep enough to

hold the tap and threading chips. It can also be used with form taps. This has

only about 1/2" of usable movement so I have to stop and reposition the

mill head during the tapping process. With large taps, the mill head is not easily

moved.

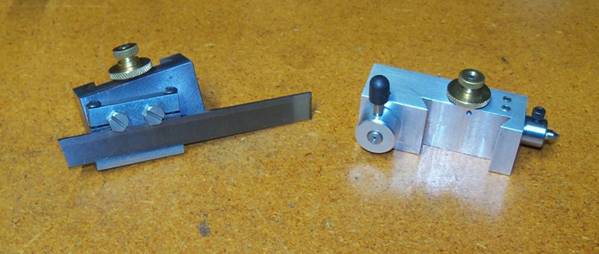

Quick Change Tool

Post Set

One

of the first things I made after building the mill was a set of quick-change tool

holders and tool post for the mini lathe. I made these out of aluminum but some

people would prefer steel. Aluminum works fine for the forces used on the mini

lathe and is easier to machine. (wear hasn't been a problem) I have now updated

the quick-change Tool Post using steel. It has a bigger clamping surface and is

a better designed Post. This was an attempt to fix a problem that turned out to

be somewhere else. (see Cross Slide Lock)

Most

holders are 1" x 1" x 2" and can be used with up to 3/8"

tooling. One is made for a 1/2" high cutoff blade and two made for a

3/8" and 1/2" boring bar. Also

some of these are now made of steel.

The

next picture shows my two latest tool holders. The one on the right is a

retractable threading tool. It can retract the cutting bit about 0.10" for

the return trip to the start of the cut. This was an easy to build design and

it works great. (It uses a 0.187" diameter tool bit) The cutoff blade

holder on the left is set at 14° for better cutoff action on steel and is

mounted to a steel holder.

A

note on tool bits: I have come to realize that smaller is better! Only a small

area of a tool bit is actually used when cutting and the smaller tool bits are

far faster and easier to sharpen.

Reciprocating File

The

winter of 20-21 was a long one because

of the pandemic, so I did more work in the shop. This motorized reciprocating

file was one of my projects. It has a little over 1" stroke and runs at

about 3 strokes per second. It has a gear motor that uses about 120 watts and

seems to be strong enough for what it does. This is designed for precession

work, not fast work and for files of about 1/4" dia. in size or less. The

knob on the motor is so I can manually lower the shaft for easier mounting of

the file. The file is placed in a 0.50" dia. steel cup and then filled

with solder (no flux) to hold it in place. The cups have a small pin in them so

after the solder cools, the files can't be pulled out or move. I use the mill

to hold the file square for soldering. The file has to be cut off and placed in

the cup upside down so that it will cut on the downward stroke. I also made one

holder for a reciprocating metal saw blade which is held in by a set screw. I

used a 0.050" thick aluminum gold anodized door kick plate to make the

sides. The project turned out quite nice.

Right Angle Mill Head

Attachment

This

project was done mainly to see if I could do it. It also required making a

spindle collar for the mill so the angle attachment would have something to

mount on. The attachment uses BOSTON 2:1 spiral bevel gears. The output shaft

is a 1.25" diameter MT3 straight socket cut down to the desired length.

That and ball bearings are put inside a surplus steel casting. (not available

anymore) The output speed is half of the input so it doubles the mill output

torque.

This

attachment requires a mill reverse switch. In the next picture you can see I

mounted it behind the control box. I had to flip the cover plate around so the

power switch was on top. This picture also gives you a view of the spindle

collar that was added. (replaced a plastic cover) When the angle attachment is

not in use, I add a knurled ring to the bottom of the spindle for easier hand

turning.

As

long as I now have a right angle mill attachment, I made a 1" saw arbor

and bearing block mount for the mill column. There is a lock lever on the block

so it and the mill lock lever have to be tightened when in use. This is a

little tricky to setup but it sure works nice.

The next picture shows its parts.

Sheet metal Hand

Brake

This

device is used to form sheet metal and I use it to make guards and covers etc.

This is a bit heavier duty then many out there you can buy. It will handle up

to 0.060" steel or 0.080" aluminum. If the parts are not very wide,

it will handle thicker material. I made it because I was a sheet metal part fabrication

engineer and I just had to have one, but it does get used.

All pictures and

content Copyright © 2007, 2009, 2020, 2021 David Denker.

All Rights Reserved.

Last Revised: Feb.

2021